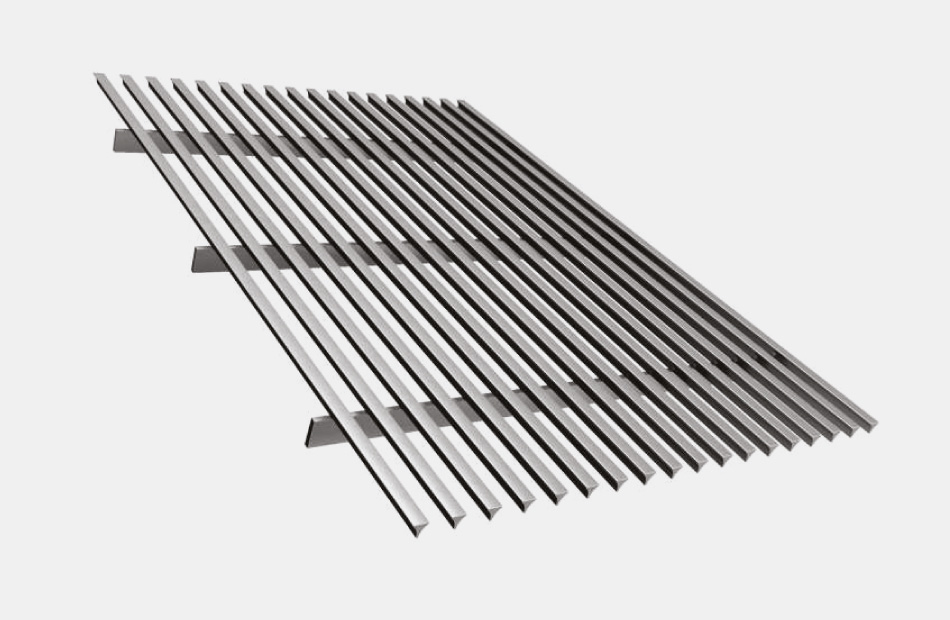

GAP wedge wire air conditioning grilles (heating grilles, ventilation grilles and Plenum ventilation grilles) are manufactured for standardised installations or custom made for unique purposes and sizes. GAP Grilles can be produced from many steel grades, specialist alloys or aluminium. With a painted, powder coated or anodised finish, we can truly tailor these wedge wire air conditioning grilles to accommodate any specific requirements.

Stainless Steel grilles allow perfect air flow & noise reduction

The constant interest we are seeing in stainless steel in the world of architecture is driven by its very high resistance to corrosion and detergents, along with its strength at both high and low temperatures. In conjunction with this versatility and durability, wedge wire stainless steel is an environmentally friendly material, offering high end aesthetic finishes and practical solutions for use in a diverse range of applications.

The innovative wedge wire design in stainless steel allows for perfect air flow and noise reduction with uncompromised strength and quality.

PROFILE SHAPE

Special shape of the profiles makes it possible to minimise airflow resistance and ensures a self-cleaning ability of the grille.

GAP SIZE

Gap size is adjusted to the required functionality. It is possible to obtain different gaps within a single grille.

SLOT DIRECTION

In order to obtain a desired visual effect, it is possible to arrange the gaps along the longer or the shorter side.

Lightweight Aluminium heating and ventilation grilles

Wedge wire Aluminium grilles for use in air conditioning and ventilation (along with associated lightweight alloys) are becoming increasingly popular for linear use in architecture and construction, largely due to the following technical properties:

- Low Specific Gravity.

- High Corrosion Resistance.

- Easy Workability.

- High thermal and electrical conductivity, and maintenance of mechanical and physical properties at low temperature.

- Compared with other metals, aluminium grilles have a much lower density.

Wedge Wire air conditioning grille options and uses

GAP’s wedge wire manufacturing process incorporates a broad spectrum of premium quality products combined with superior knowledge to realise the ultimate ventilation and air conditioning grille solution for each and every application. The preparation and treatment of numerous metals, from stainless steel to aluminium affords endless material options, whilst at the same time taking into account the individual conditions of use, resistance to weathering, design requirements and budgetary constraints.

In public, commercial and private sector air conditioning grille installations, our wedge wire Stainless Steel and Aluminium heating and ventilation grilles offer the perfect solution for:

Residential Buildings • Ventilation Grilles • Air Conditioning Grilles • Production Halls • Offices • Showrooms • Swimming Pools & Sports Facilities • Many Prestigious Applications Worldwide and so on

Shown opposite (top)

Stainless Steel wedge wire air conditioning grilles at Centre Point luxury accommodation in London.

View project

Shown opposite (bottom)

Bespoke radial and linear Stainless Steel wedge wire ventilation grilles at Goldman Sachs Group London Headquarters

View project

Plenum Box Grille & Plenum Grilles for Air Conditioning and Ventilation

Wedge Wire is an ideal solution for plenum box grille applications. A plenum is a separate space provided for air circulation for heating, ventilation, and air-conditioning between the structural ceiling and a drop-down ceiling. An essential component of any HVAC system – a plenum grille (plenum box grille) distributes conditioned air throughout the building and provides a return path for unconditioned air,

How a Plenum Box Grille Works

An air distribution box that is directly connected to the heating, ventilation, and air conditioning equipment’s supply outlet is known as a plenum box.

This warms or cools the air to make a climate agreeable.

The ventilation work disseminates the warmed or cooled air to the singular rooms associated with the plenum box. This case contains positive pneumatic stress. The principal capability of a plenum box is to balance the tension for an even conveyance.

The Plenum box permits square grilles and diffusers to associate with round conduits.

For Plenum Box Grille enquiries, please contact us

Electropolishing

Electropolishing utilises a surface technique whereby the Grille / Mesh is brightened, smoothed and protected against corrosion. It also gives surface hardening when applied to chromium-nickel steel. In essence, electropolished surfaces provide greater aesthetics and durability.

Pickle and Passivation

Pickle and Passivation provides a uniform appearance, removing all welding blemishes during the process. Passivation leads to the formation of an oxide layer.

This makes the surface hard and tight, whilst isolating the metal from corrosive environmental impacts.

Shot Blasting

Shot Blasting is an abrasive technique using ceramic or glass micro-balls. The process provides a uniform, dulled surface which eliminates all processing discolorations. GAP can provide wedge wire heating and ventilation grilles with an anti-slip finish (when used in outdoor landmark features). Our standard 240 grit linished finish is by far the most readily used.

Zinc Coating

Electro or hot dipped zinc coating protects the product against corrosion and can often be added as the final finish for an industrial appearance or as a primer for powder coating. In a corrosive environment zinc coating provides significantly higher corrosion resistance properties than a non zinc coated steel finish.

Powder Coating

Powder coating is a technique that offers excellent corrosion protection and is available in a wide range of colours. Aluminium, carbon steel and galvanised steel products are all suitable for this process. It’s also an ideal finish for both indoor and outdoor applications.

Anodising

Anodising is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant and anodic oxide finish. Anodising is accomplished by immersing the aluminium into an acid electrolyte bath and passing an electric current through the medium.

DOWNLOADS

Wedge Wire Air Conditioning Heating Grilles and Plenum Ventilation Grilles

Information & enquiries

For more information and enquiries regarding perforated steel street furniture, please click to contact Gap Architecture through our enquiry form. A member of our team is on hand and ready to help deal with your enquiry.

Telephone: +44 (0) 1777 710710

Request a callback

Alternatively, if you leave your name and contact telephone number, a member of our team will give you a call as soon as they can to discuss your requirements: